The rosette is the design that surrounds the sound hole. Using my old 1950 Gibson J-50 as my inspiration, I’m going for a very simple, almost utilitarian, yet classic look. I’ve kept the thin 1/8” overall width, but I’m using three rings featuring wenge and holly, the same woods I’m using for the binding and elsewhere on the guitar.

Top

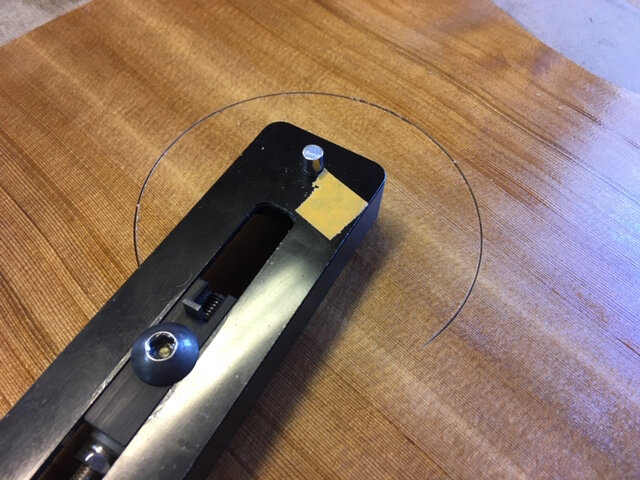

Top is mounted on a locater pin for the sound hole cutout.

Cutting 1

Circle cutting tool is used to cut outside edge of rosette groove into the top.

Cutting 2

Both inside and outside edges of rosette are now defined.

Router Plane

Router plane is used to remove the material between the inside and outside lines. Depth of cut is 2mm into the 3.5mm top.

Removing wood

Inside material is slowly and carefully removed.

Ready for inlay

1/8” wide “trough” is now ready to accept inlaid wooden rings.

Wenge

Here I begin slicing the wenge for the center ring of the rosette.

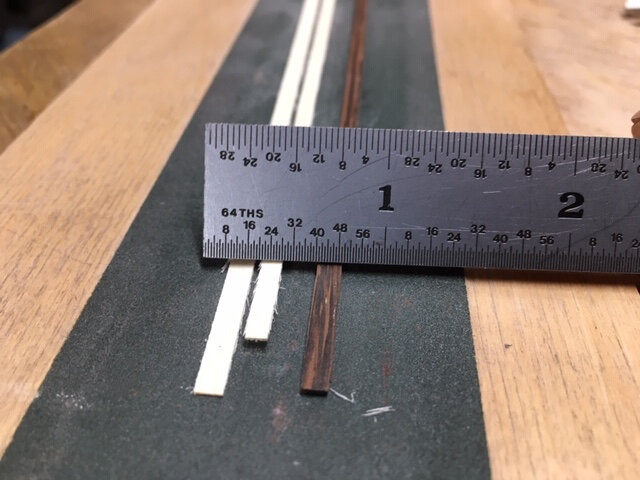

Triple Strips

Here are the two strips of holly and single strip of wenge sanded to final thickness and height.

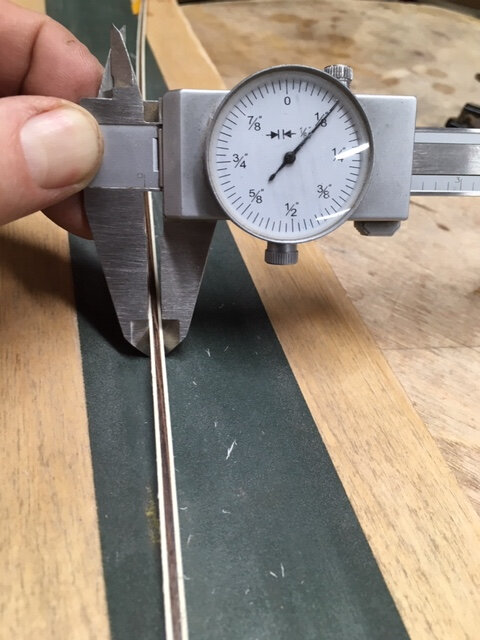

Measuring final thickness

All three strips combined for total 1/8” thickness.

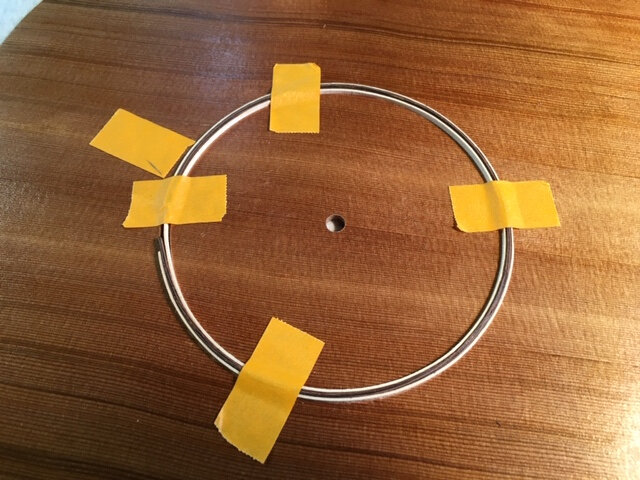

Bending

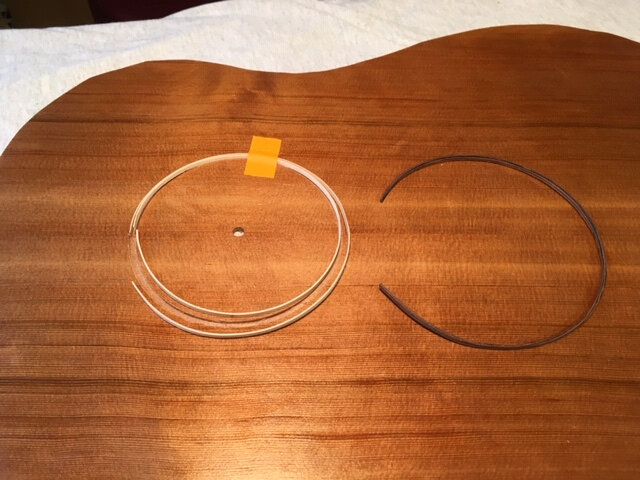

After wetting and heating the wood strips, I bend them around the correct size jig to form the rosette rings.

Ready for fitting

Bent rings are ready to be dry fitted into the rosette trough.

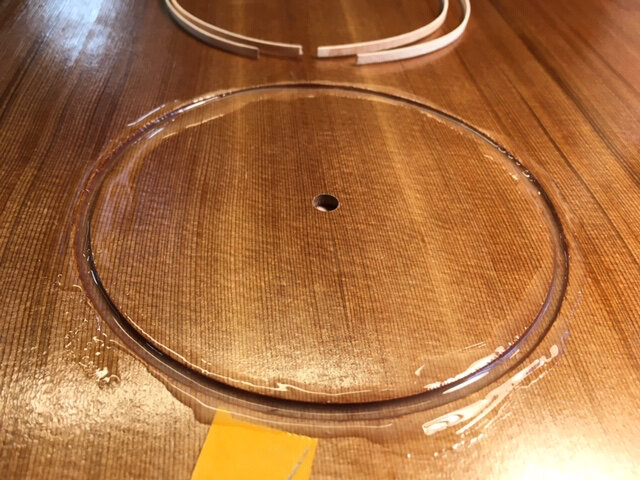

Dry fit

The dry fit confirms correct thickness of the rings.

Fish Glue

Glue up begins!

Rings inserted

Rings are carefully but quickly inserted into the wet glue.

Next day...

Glue is dry!

Planing

Hand plane is used to bring height of wood rings flush with top.

Lie-Nielsen

Beautiful Lie-Nielsen hand plane set to remove a thin ribbon of shavings with each pass.

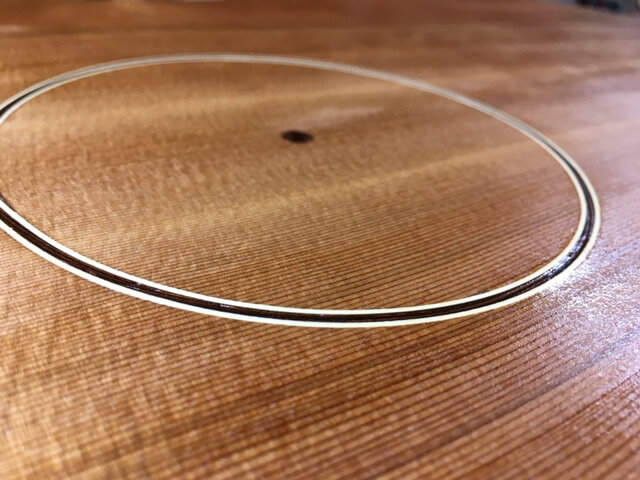

Sanded

After planing, sanding brings the wood rings flush with top. Sealer coat is removed during the sanding process.

Sealer

Sealer coat of shellac is re-applied.

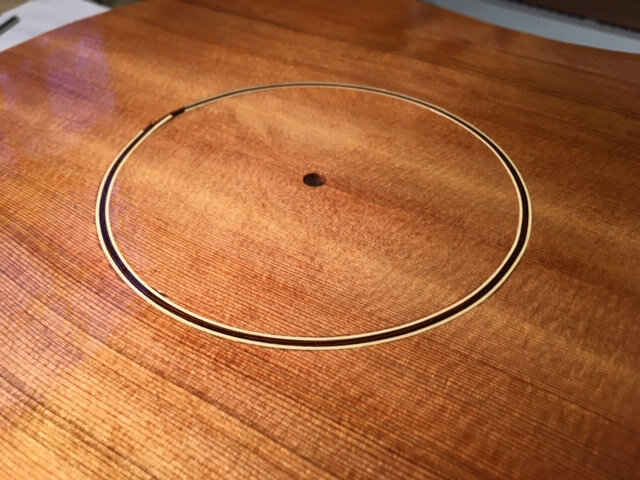

2nd coat

2nd coat applied

Final

3rd and final sealer coat… ain’t she pretty?